Opc Server Modbus Tcp Free

Your latest post has provided more detail. However, how many floats (or registers) are you transferring in a single transaction (poll)?

That makes a big difference as a lot of the delay can be the time it takes to turn a message around. For example, if you are transferring 2 registers per polling cycle, the average throughput (registers per second) will be much slower than if you are transferring the maximum of 125 registers per polling cycle. In fact, the average time to conduct a poll for a large amount of data over Modbus/TCP (over Ethernet) is typically not that much greater than the time to poll for a small amount of data. That's why you need to also count the transaction rate (number of polls per second). Also, the message overhead is the same in each case, so the ratio of overhead to data is much greater when you are transferring a few registers at a time than when you are transferring many.

That will matter more on a serial connection where the link itself can be the bottleneck. As far as the OPC rate of 4800 register per second (2400 floats per second), the limit there will be related to how OPC handles the data. I have benchmarked Modbus/TCP servers that don't use OPC, and they are typically much, much faster than that. So, at this point it's hard to say where the bottleneck is. How many registers are you transferring in each transaction (poll)? What baud rate are you using for RTU?

To communicate directly between the PLCs, using serial on one side and Ethernet on the other, you can use the MBX Bridge Suite. But the throughput is going to be limited by the slower network, so I don't know that you'll get much better performance that way than with the direct serial connection. If you need to pass data between the OPC server and the other PLC, you can use an MBX OPC Premier Suite, which will let you talk to both PLCs and the existing OPC server, passing data among any of them. But a simpler configuration would be to just replace the existing OPC server with the MBX OPC Premier server. That will let you get data from both PLCs into the server, and pass it between the two PLCs, giving you everything you need, without having to deal with server-to-server transfers.

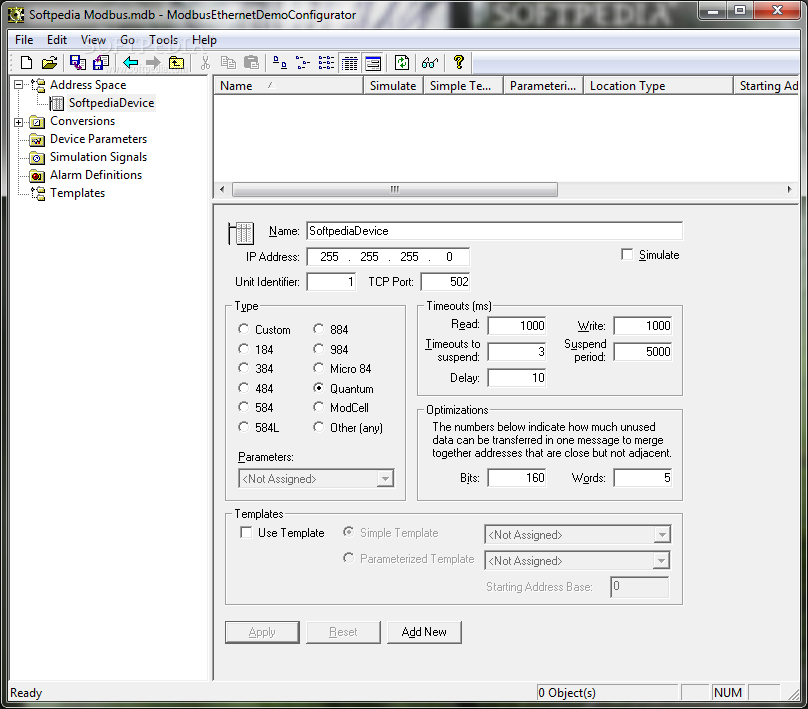

Details on both products are available at www.cyberlogic.com. Dan Muller Cyberlogic. Typically if I am contacted by a customer that has an OPC server and they want to get that data outputed as Modbus data, usually for a Delta V or other DCS system to read, I have them use our LinkMaster bridge product and our Modbus TCP Ethernet driver. First I have them configure the Modbus Ethernet driver using the local IP or 127.0.0.1 which turns the device in our server into a Modbus Etherent Slave.

MODBUS OPC SERVER FREE. S7 MPI,S7 PPI, Profinet (S7 1200), Modbus RTU, Modbus TCP/IP, Host-Link protocols(Omron), Mewtocol protocols(Panasonic). Free OPC Products. Category Product Download Vendor; OPC Server. Modbus, Modbus TCP, and Modbus Plus OPC Server Open Automation Software.

They then create static tags to for each register that they want the Modbus Etherent Master to read. ( they do not have to create the tags but if they have a lot of data to transfer it is easier to keep track of everything.) Next the configure the LinkMaster so that it is connected to the other server and our server. Using drag and drop they can browse and select OPC items from their server and drop them in LinkMaster to create link items.

These OPc Items will be the inputs to the link they then select the tag that they want to receive the data in our server and drop it onto the link. It becomes the output of the link. With that you are reading data form the server and writing it to modbus. You can create links that go the other way in case you want to write data to the server from the Modbus Master. Download Derivatives Financial Markets Stochastic Volatility Pdf. You could also have our server be the modbus master and write data out to a Modbus slave device.

Fred Loveless Kepware Technologies. You have clicked on the '?'

Button for search help. To search the site, enter your search terms in the box labeled 'search the site' and hit Enter. Some tips for better search results. • Precede each search term with a '+', as follows: • +Modbus +TCP Otherwise, any post with either term will match. • Use double quotes around phrases, as follows: • +'Allen Bradley' +ethernetOtherwise, posts containing these words in separate locations will match. • To exclude a word, precede it with a '-', as follows: • +Modbus -Plus This will return only posts containing 'Modbus' but NOT containing 'Plus'. • Note that common words (and, that, etc.) and words shorter than 2 characters are automatically excluded from searches.

Select the categories for which you would like to see messages displayed. Applications Application Questions and Problems Automation Business The Business of Automation and Control Communications Communications systems and equipment. Engineering Engineering and workplace issues.

HMI Human-Machine Interface and SCADA. Mastering The World Of Psychology 5th Edition Pdf Download. Information Information resources, documentation. Languages Programming languages. Motion Control Motion control, servos, steppers, etc. Networking Local and wide area networking in factory automation. Open Control Open interfaces, software and hardware PCs in Automation Computers in manufacturing; also hardware discussion.

PLCs PLCs and related questions. Power Generation Power generation equipment control. Process Control Continuous process industries, DCS questions. Sensors Sensor technologies. Software in Automation Software, including programming, OS issues, etc.

Product Overview The Modbus Suite for KEPServerEX is a collection of Modbus drivers, bundled together for convenience. It provides application access—including OPC data access—to Modbus-compatible devices, enabling users to easily configure fast and reliable Modbus connections. The Modbus Suite supports multiple Modbus protocols (including TCP, RTU, ASCII, and more) from a single license. Used across many industries worldwide, Modbus is recognized as a simple and universal industrial automation communications protocol. Kepware’s Modbus drivers support a wide variety of Modbus-compatible devices and models, and both master and slave connections.

As a member of the Modbus Organization—an independent group dedicated to the adoption and evolution of Modbus protocols across multiple market segments—Kepware is committed to the continuous improvement of its Modbus solutions. Kepware’s Modbus Suite is included in the Modbus Organization product database. Supported Devices and Networks • TCP/IP Ethernet (Master/Slave) • RS-232 and RS-485 Serial (Master/Slave) • Modicon • Enron • Omni • Daniel • Instromet • Dynamic Fluid Meters • Roxar RFM • Mailbox • Elliot • Fluenta FGM • DGH DAQ Note: Unlisted devices may also be supported; please. What Is a Suite? Is more than an —it's a connectivity platform for industrial automation and IoT. Simply download KEPServerEX, and then select from Kepware's library of more than 150 device drivers, client drivers, and advanced plug-ins to fit the communication requirements unique to your industrial control system.

A suite is a collection of drivers and advanced plug-ins for KEPServerEX. These products have been bundled into suites by vertical industry, device manufacturer, or industrial application for the convenience of our customers. Additional suites can be licensed on demand as connectivity needs evolve.